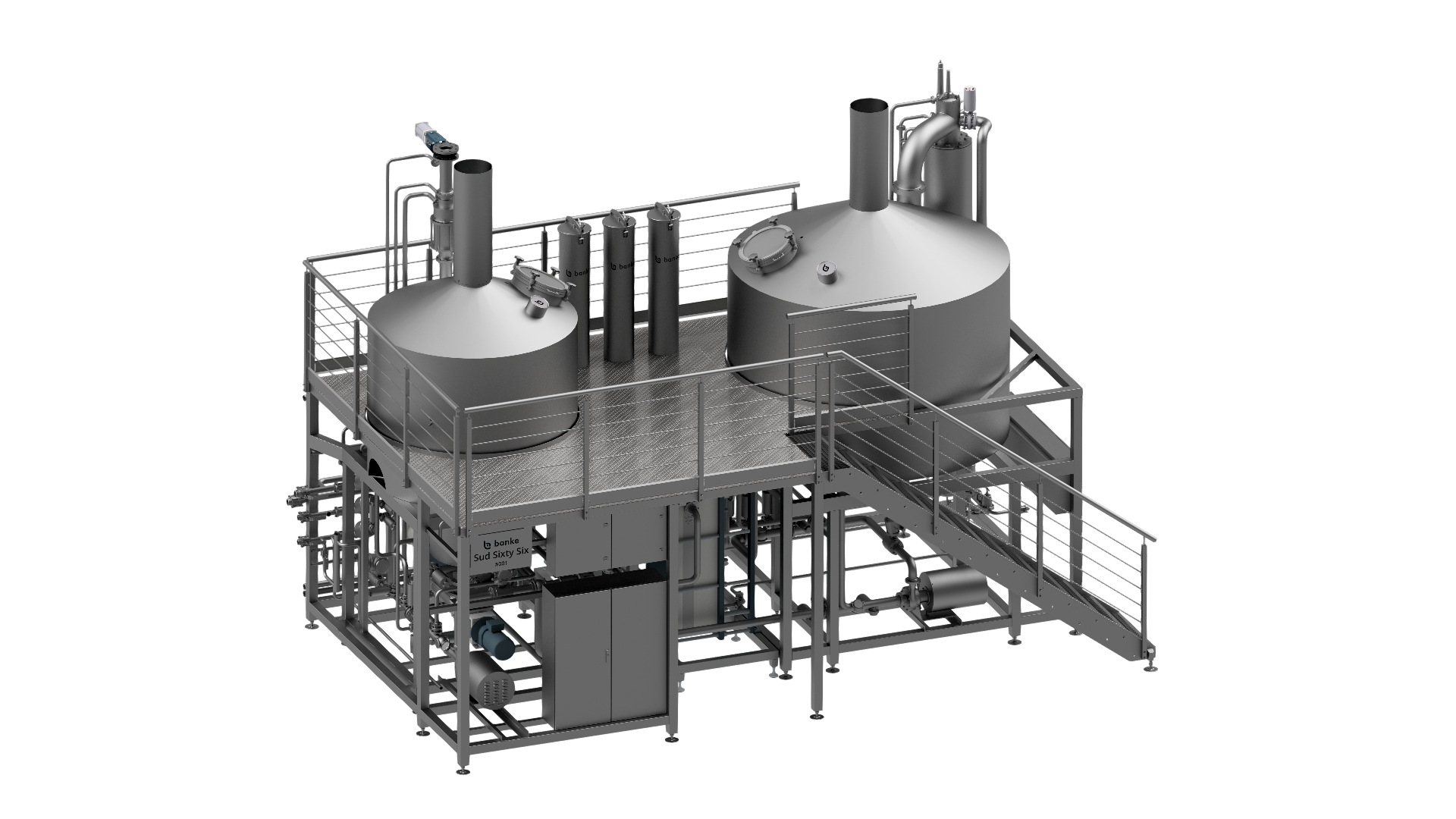

SUD Sixty Six - Compact Brewhouse

The Sud Sixty Six is a patented, compact, sustainable, and flexible brewing system for up to 3 brews per shift with a specific energy consumption of < 6 kWh/hl.

This compact brewing system uniquely combines crucial advantages in technology, construction, and cost-effectiveness: maximum production capacity, pre-piped, pre-wired, and compact.

With only 60 minutes of lautering time, the Sud Sixty Six achieves a revolutionary 6 brews per day - all with just two brewing vessels.