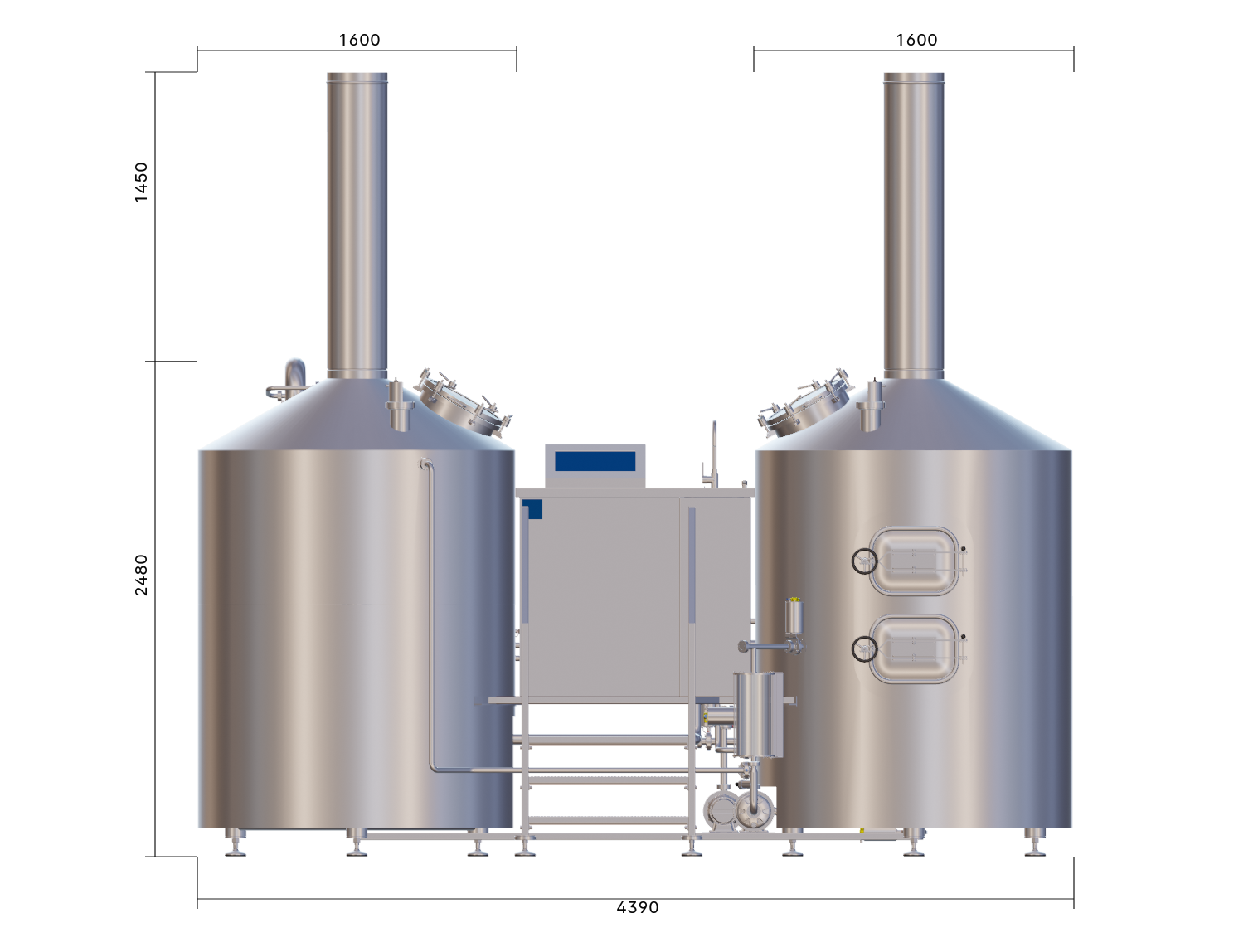

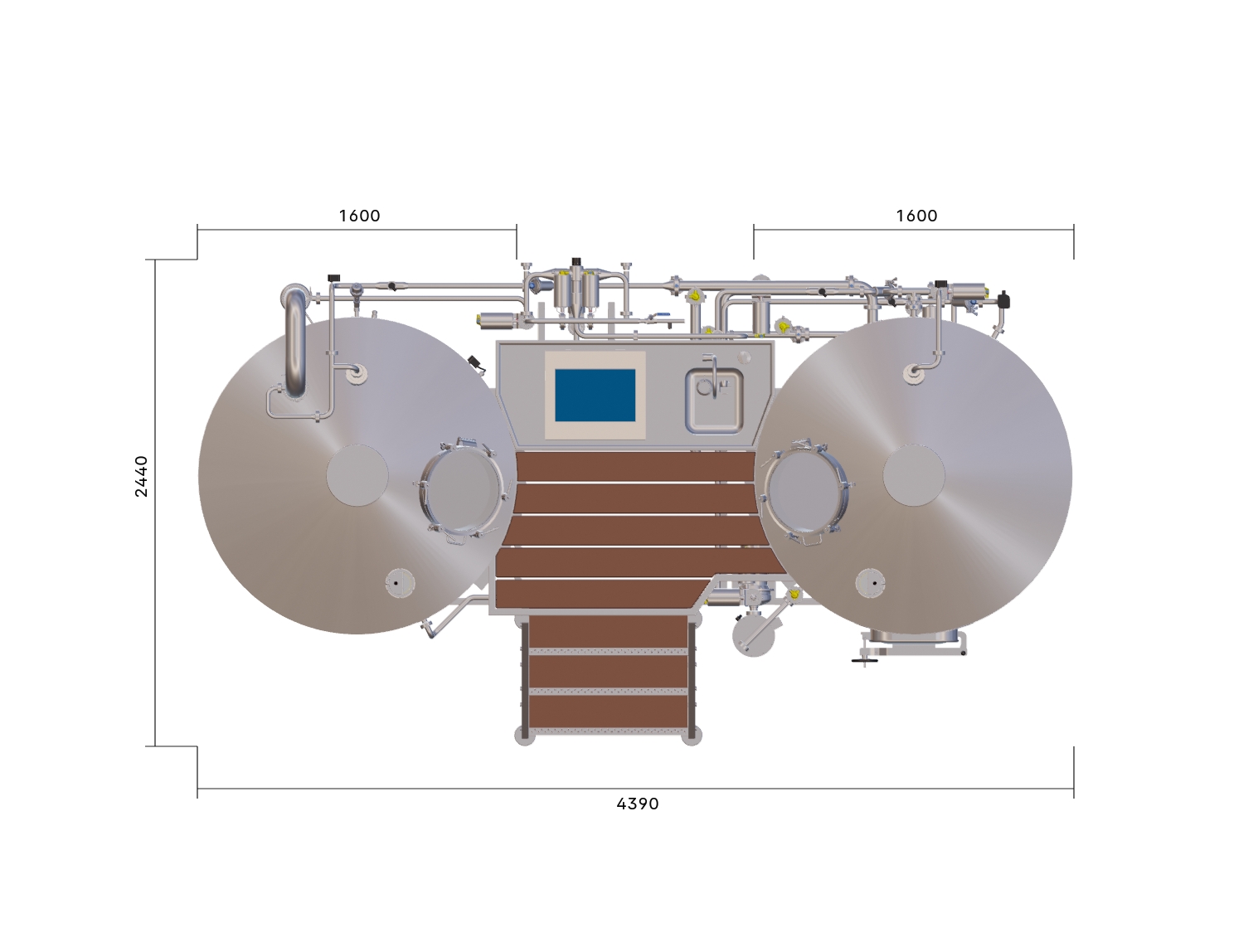

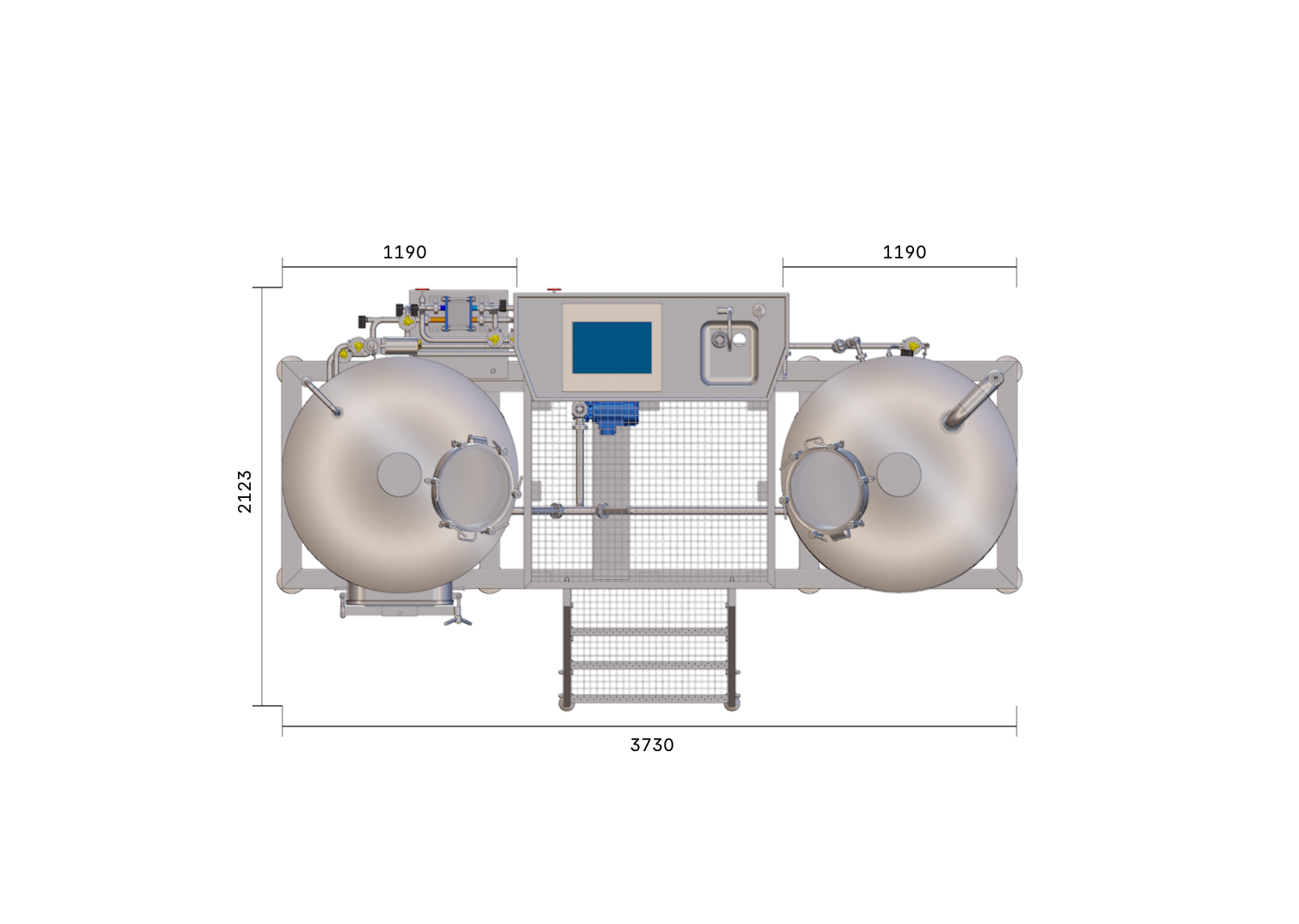

Compact 3-Vessel Brewhouse in 5 hl and 10 hl Batch Size

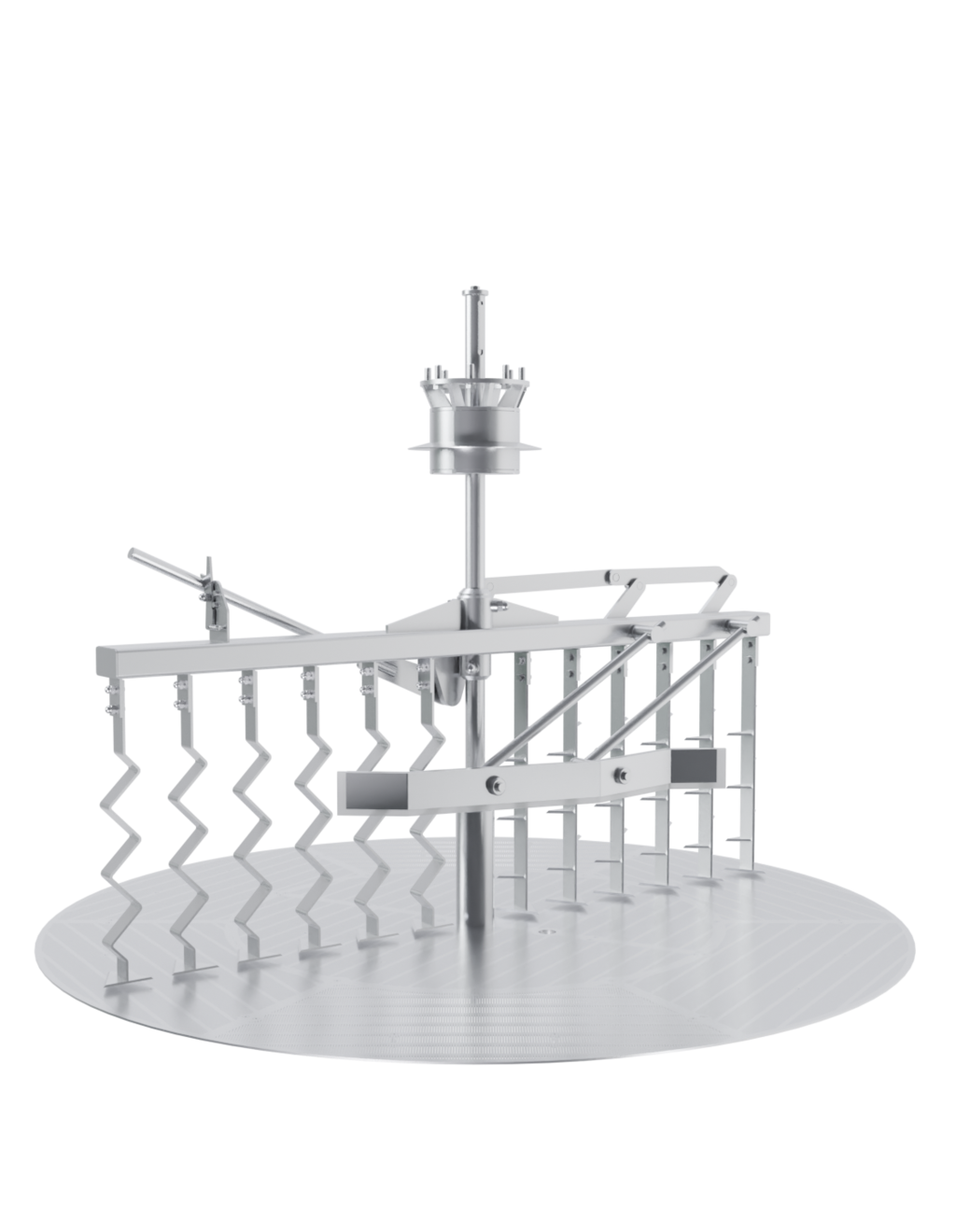

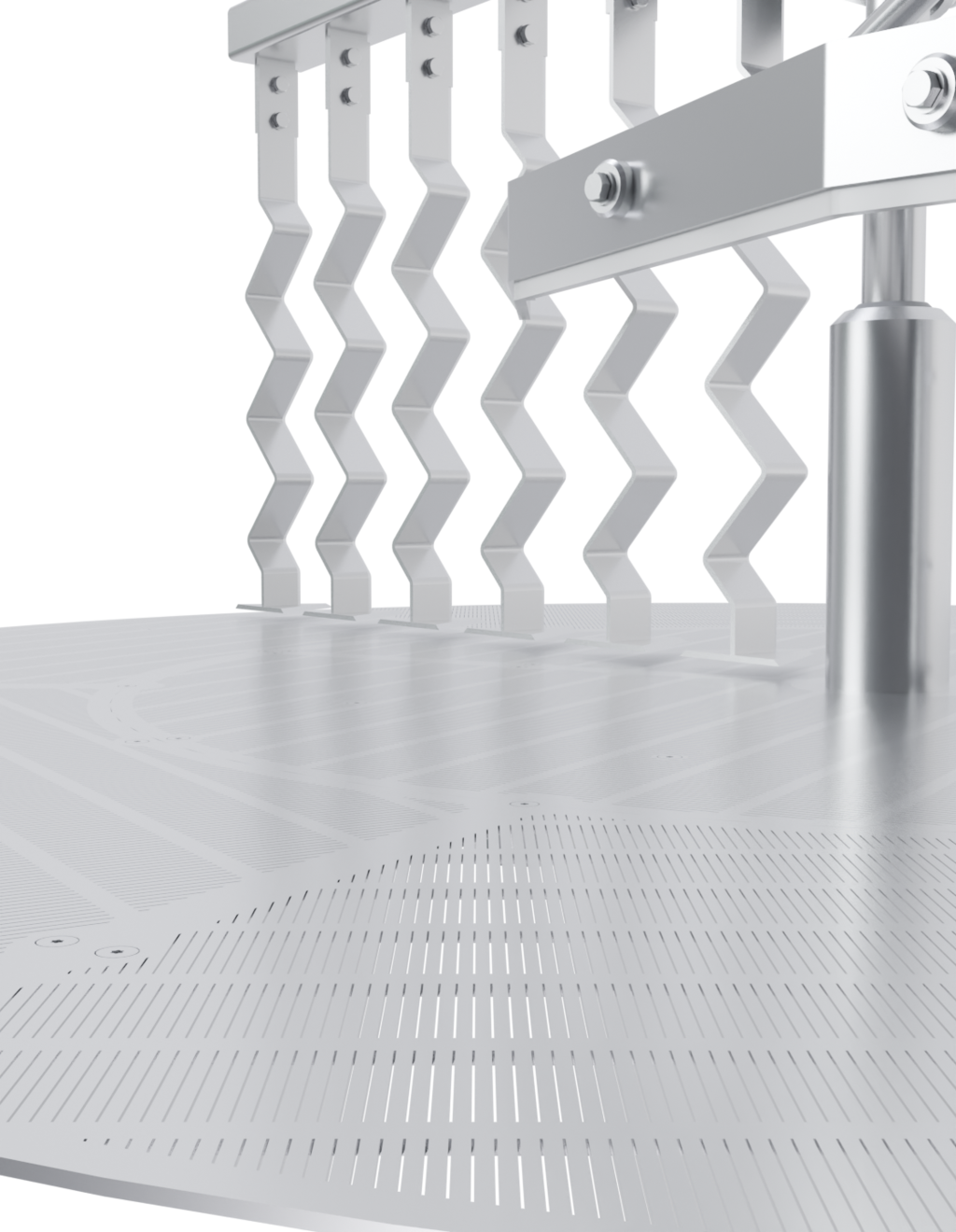

The EDS Craft Compact is a compact brewhouse that convinces with its appealing minimalist design. Despite its small footprint, it offers the full functionality of a large brewhouse, making it the ideal choice for gastro businesses. Available in various finishes such as copper and numerous other combinations, the Craft Compact seamlessly integrates into any environment while delivering professional brewing results in the smallest of spaces.